Four Process Design Methods of Rotating Flash Dryer

Source: | Date:

2016-07-05

| Hits:

Keywords旋转闪蒸干燥机工艺

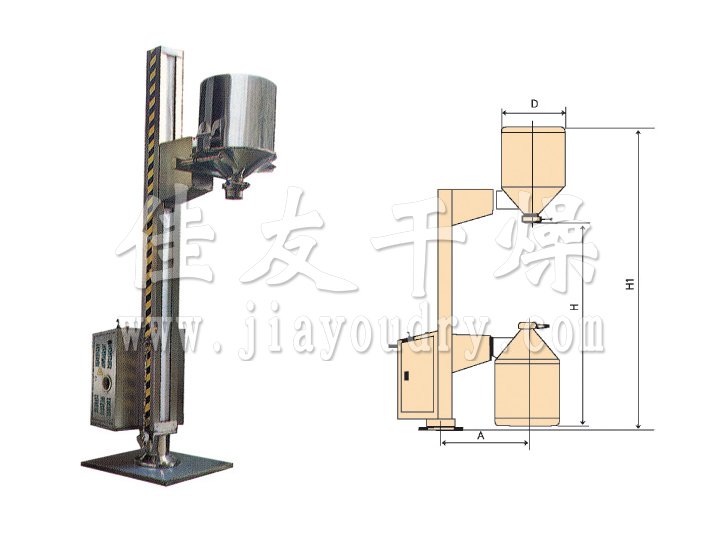

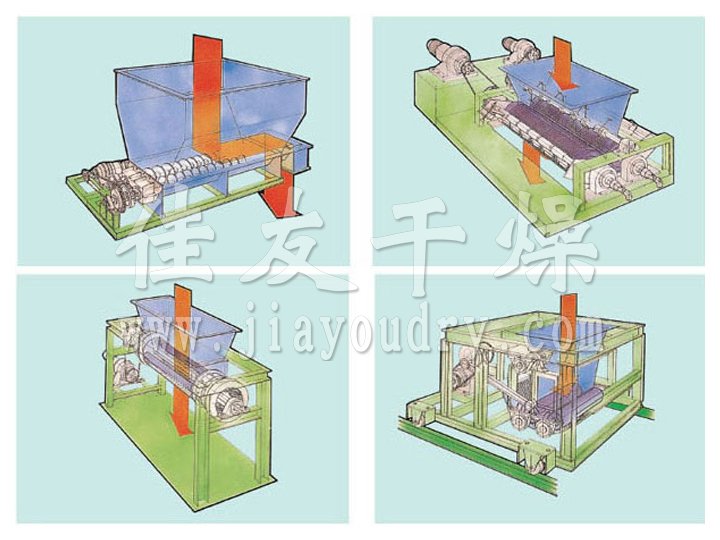

Rotary flash dryer The new equipment uses a variety of advanced devices, such as the use of a variety of feeding devices, so that continuous feeding stability, the feeding process does not produce bridging phenomenon; dryer at the bottom of a special cooling device to avoid the material in the bottom of the high temperature area The use of special air pressure sealing device and bearing cooling device to effectively extend the life of the transmission part; the use of special sub-wind device, reducing the resistance of the device, and effectively provide the dryer air flow; drying room With the classification of the ring and the cyclone, you can adjust the fineness of materials and the final moisture; the use of mixing crushing device, the material has a strong shear, blowing, rotating role; the use of air filters, cyclones, bag filter , Effectively remove dust, to avoid environmental and material pollution. The equipment mass transfer heat transfer, high production intensity, short drying time, material retention time is short. So today by the experienced Changzhou area drying equipment manufacturers to introduce the rotary flash dryer four process design method!

First, the drying room to determine

Rotary flash dryer to deal with the evaporation strength of some materials, volume heating method is the theoretical design of rotary flash dryer method, but the most critical volume of this method to determine the heat coefficient is difficult, so the lack of operability. Evaporation intensity method is the volume of the indirect method of heat, as long as there is a certain experimental data can be calculated, is often used in industrial design methods. Evaporation intensity method is based on the amount of evaporation and evaporation intensity calculated the size of the drying chamber, and then according to the relationship between diameter and height to calculate the effective height.

Second, the drying chamber diameter

Another method is to calculate the required air usage by material balance and heat balance, and then determine the diameter of the dryer according to the air velocity range.

Third, the height of the dryer and grading particle size

From the hot air distributor out of the hot air into the tangential direction through the annular gap into the drying room, drying room materials in the hot air blowing under the action of the stirrer and under the action of spiral rotation up and down movement. In the study of the movement of smaller particles in the centrifugal force field, the effect of gravity is small and can be neglected.

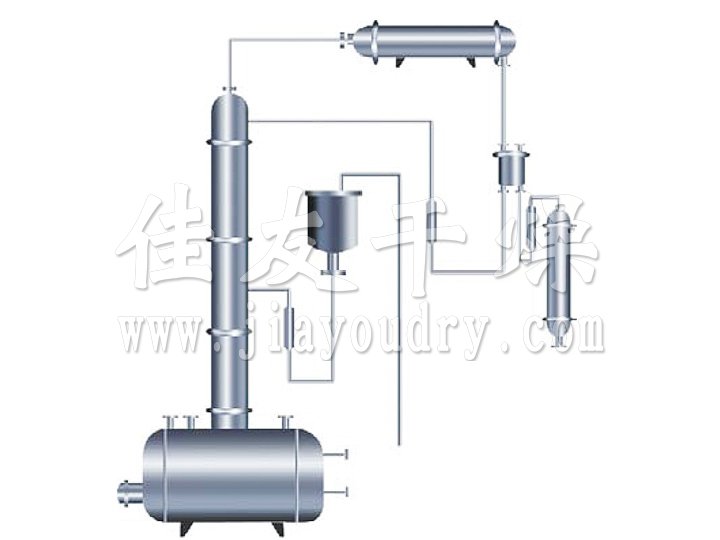

Fourth, the application of rotary flash dryer

Part of the rotary flash dryer operating conditions, the upper part of the drying chamber with a grading ring, its role is mainly to make larger or no dry material and qualified products separated from the block in the drying room can effectively ensure product size and moisture requirements. Replacement of different diameter of the grading ring to meet the product size requirements. Cone hot air at the mouth with a cold air protection, to prevent the material and high temperature air contact overheating metamorphism. Drying system for the closed, but also in the micro-negative pressure operation, the dust does not leak, protect the production environment, safety and health.

Copyright © 2017 Jiayou Drying Engineering

Copyright © 2017 Jiayou Drying Engineering