- Business

- Link

Drying equipment series

ZLPG Chinese Herbal Medicine Extract Spray Dryer

DESCRIPTION

Chinese herbal medicine extract is refined from root, stem and leaves of plants, and contains high sugar especially from alcoholization process, which is easy melted at high temperature, Normal centrifugal spring cannot meet its drying requirement. For this reason, we have developed such a dryer especially used for Chinese herbal medicine extract on the basis of our experiences and tests. It has been popularized and used by some famous pharmaceutical manufacturers.

WORKING PRINCIPLE

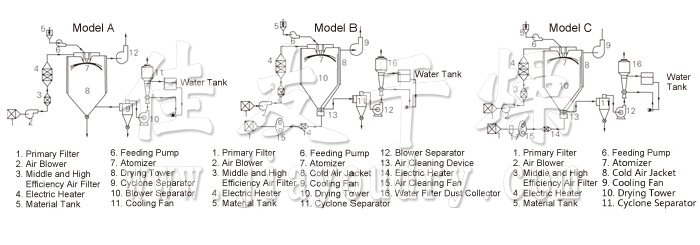

After fresh air is filtered and heated, it enters into the air distributor which on the top of the drier. The hot air in spiral form equably enters into the drying room. When liquid raw material is passed through the high-speed centrifugal sprayer on the top of the tower, it will be rotated and sprayed into the extreme slim mist liquid beads. Raw material can be dried to the final products instantly while it contact with the heated air. Finished products are discharged continuously from bottom of the drying tower and cyclones segregator. Wasted air is discharged from the blower.

FEATURES

1.The tower is equipped with a cold air jacket;

2.The towers is equipped with automatic vibration device;

3.There are quick opening cleaning hole and sewage hole in the tower and piping system;

4.The dryer can be equipped with automatic control & thermostatic feeding tank;

5.Manual supplied accessories for the high-pressure washing system is available;

6.The material contacting area is constructed by stainless steel; (or use all stainless steel);

7.The material is collected by two-stage cyclone dust collector. Or use a cyclone operator and wet dust collector instead;

8.The inlet air temperature can be controlled by a continuous automatic control device.

9.The dryer can be equipped with gas cleaning device.

Technical Parameter

| Item \ Model | ZLPG-15 | ZLPG-20 | ZLPG-25 | ZLPG-32 | ZLPG-38 | ZLPG-40 | ZLPG-47 | ZLPG-52 | ZLPG-58 | |

| Evaporated amount of moisture (kg/h) | 5 | 10 | 25 | 50 | 80 | 100 | 150 | 200 | 300 | |

| Treated amount of raw material liguid (kg/h) | 6-7 | 12-14 | 25-34 | 50-68 | 80-108 | 100-135 | 150-203 | 200-270 | 300-406 | |

| Output of finished procuct (kg/h) | 1-2 | 2-4 | 4.8-7.2 | 9.2-14 | 14.8-22.4 | 18.4-28 | 28-42 | 36.8-56.4 | 55-85 | |

| Solid content of damp raw material (%) | 18-25 | |||||||||

| Ratio of moisture of finished product (%) | 3-5 | |||||||||

| Electric power (kw) | 36 | 45 | 63 | 99 | 132 | 153 | 204 | 246 | 330 | |

| Heating source | steam plus electricity | |||||||||

| Colleting way of product and its efficiency | two-grade cyclone duster of one-grade cyclone duster and one-grade damp duster ≥95% | |||||||||

| Automatic control meters and instruments | indicator of temperature of hot air and humidity of air exhaust | |||||||||

| Temperature of air in | 150-200 | |||||||||

| Temperature of air out | 80-100 | |||||||||

| Overal dimensions (mm) | L | 5000 | 5500 | 7000 | 8000 | 9800 | 11000 | 12200 | 14100 | 15000 |

| W | 3000 | 3500 | 4000 | 5000 | 5700 | 6200 | 7000 | 7800 | 9000 | |

| H | 4500 | 4600 | 5200 | 6500 | 7600 | 8100 | 9000 | 9850 | 11100 | |

Note:*The actual diamensions are in accordance with the customer’s requirement,the above dimensions are only for reference.

* The above is the largest evaporation.

- 2017-02-12 > Application of Spray Dry Desulphurization Technology in Protecting Ecological Environment

- 2017-01-17 > Comparison of Powder Yield Rate of Special Extract and High - speed Spray Dryer

- 2017-03-27 > Jiayou dry disc dry successfully shipped

- 2017-03-06 > Analysis on the Application of Eight Kinds of Drying Equipment in Chemical Industry

- 2016-12-19 > Belt dryer in the course of the use of common faults and maintenance

- 2016-11-23 > Application Range and Type Selection of Belt Dryer

- 2016-10-17 > Development Status of High Efficiency Mixed Granulator for Calcium Carbonate Industry

- 2016-09-27 > Safe use of hot air circulation oven and four points of attention

- 2016-08-06 > Rice dryer market will also be a new trend

- 2016-07-05 > Four Process Design Methods of Rotating Flash Dryer

Copyright © 2017 Jiayou Drying Engineering

Copyright © 2017 Jiayou Drying Engineering